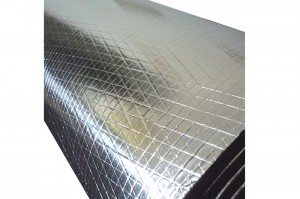

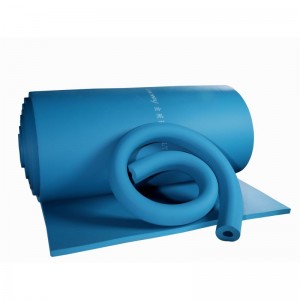

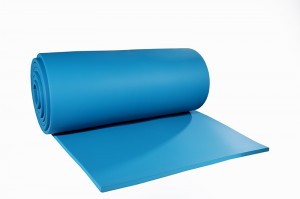

Tabula spumae e caucciu Kingflex, lamina aluminio obducta,

Descriptio

Materiae insulationis thermalis ex spuma gummi Kingflex technologia modernissima ex exteris regionibus inducta et linea productionis automatica producuntur, gummi nitrile butadieno (NBR) et polyvinylchlorido (PVC) praeclaris functionibus ut materiis principalibus, necnon per processus speciales inhumationis, sulfurationis, spumationis, etc.

Dimensio Standardis

| Dimensio Kingflex | |||||||

| Crassitudo | Latitudo 1m | Latitudo 1.2m | Latitudo 1.5m | ||||

| Unciae | mm | Magnitudo (L*A) | ㎡/Volumen | Magnitudo (L*A) | ㎡/Volumen | Magnitudo (L*A) | ㎡/Volumen |

| 1/4" | 6 | Triginta × unum | 30 | Triginta × 1.2 | 36 | 30 × 1.5 | 45 |

| 3/8" | 10 | Viginti × unum | 20 | Viginti × 1.2 | 24 | XX × I.V | 30 |

| Dimidium unciae | 13 | 15 × 1 | 15 | 15 × 1.2 | 18 | 15 × 1.5 | 22.5 |

| ¾" | 19 | Decem × unum | 10 | 10 × 1.2 | 12 | 10 × 1.5 | 15 |

| 1" | 25 | Octo × unum | 8 | Octo × 1.2 | 9.6 | Octo × 1.5 | 12 |

| 1 1/4" | 32 | Sex × unum | 6 | Sex × 1.2 | 7.2 | Sex × 1.5 | 9 |

| 1 1/2" | 40 | Quinque × unum | 5 | 5 × 1.2 | 6 | 5 × 1.5 | 7.5 |

| 2" | 50 | 4 × 1 | 4 | 4 × 1.2 | 4.8 | 4 × 1.5 | 6 |

Scheda Datorum Technica

| Data Technica Kingflex | |||

| Possessio | Unitas | Valor | Methodus Probationis |

| Ambitus temperaturae | °C | (-50 - 110) | GB/T 17794-1999 |

| Ambitus densitatis | kg/m³ | 45-65 kg/m³ | ASTM D1667 |

| Permeabilitas vaporis aquae | kg/(mspa) | ≤0.91×10﹣¹³ | DIN 52 615 BS 4370 Pars 2 1973 |

| μ | - | ≥10000 | |

| Conductivitas Thermalis | W/(mk) | ≤0.030 (-20°C) | ASTM C 518 |

| ≤0.032 (0°C) | |||

| ≤0.036 (40°C) | |||

| Classificatio Ignis | - | Classis 0 et Classis 1 | BS 476 Pars 6 pars 7 |

| Index Propagationis Flammae et Fumi Evoluti |

| XXV/L | ASTM E 84 |

| Index Oxygenii |

| ≥36 | GB/T 2406, ISO4589 |

| Absorptio Aquae, % per Volumen | % | XX% | ASTM C209 |

| Stabilitas Dimensionis |

| ≤5 | ASTM C534 |

| Resistentia fungorum | - | Bonus | ASTM XXI |

| Resistentia ozoni | Bonus | GB/T 7762-1987 | |

| Resistentia ad UV et tempestates | Bonus | ASTM G23 | |

Commoda producti

Laminae spumae e gummi aluminio factae proprietates excellentes habent, ut mollitiem, resistentiam frigoris, resistentiam caloris, ignifugam, resistentiam aquae, conductivitatem thermalem humilem, absorptionem ictus, absorptionem soni, et cetera.

Societas Nostra

Exhibitio societatis

Certificatum

Categoriae productorum

-

Telephonum

-

Epistula electronica

-

Whatsapp