Lamina Spumae Rubbericae Insulationis Thermalis Kingflex

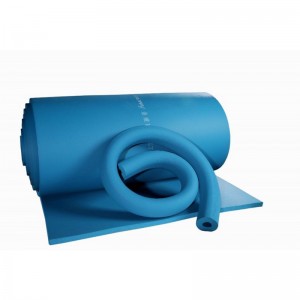

Descriptio

Structura expansa cellularum clausarum efficit ut insulatio efficax sit. Fabricatur sine usu CFC, HFC, vel HCFC. Lamina spumae e gummi insulationis thermalis Kingflex etiam efficax est ad strepitum HVAC reducendum. In systematibus frigidis, crassitudines insulationis computatae sunt ad condensationem in superficie externa insulationis moderandam, ut in tabula commendationum crassitudinis demonstratur.

Dimensio Standardis

| Dimensio Kingflex | |||||||

| Tcrassitudo | Wmensa 1 | Wlatitudo 1.2m | Wlatitudo 1.5m | ||||

| Unciae | mm | Magnitudo (L*A) | ㎡/Volumen | Magnitudo (L*A) | ㎡/Volumen | Magnitudo (L*A) | ㎡/Volumen |

| 1/4" | 6 | Triginta × unum | 30 | Triginta × 1.2 | 36 | 30 × 1.5 | 45 |

| 3/8" | 10 | Viginti × unum | 20 | Viginti × 1.2 | 24 | XX × I.V | 30 |

| Dimidium unciae | 13 | 15 × 1 | 15 | 15 × 1.2 | 18 | 15 × 1.5 | 22.5 |

| ¾" | 19 | Decem × unum | 10 | 10 × 1.2 | 12 | 10 × 1.5 | 15 |

| 1" | 25 | Octo × unum | 8 | Octo × 1.2 | 9.6 | Octo × 1.5 | 12 |

| 1 1/4" | 32 | Sex × unum | 6 | Sex × 1.2 | 7.2 | Sex × 1.5 | 9 |

| 1 1/2" | 40 | Quinque × unum | 5 | 5 × 1.2 | 6 | 5 × 1.5 | 7.5 |

| 2" | 50 | 4 × 1 | 4 | 4 × 1.2 | 4.8 | 4 × 1.5 | 6 |

Scheda Datorum Technica

| Data Technica Kingflex | |||

| Possessio | Unitas | Valor | Methodus Probationis |

| Ambitus temperaturae | °C | (-50 - 110) | GB/T 17794-1999 |

| Ambitus densitatis | kg/m³ | 45-65 kg/m³ | ASTM D1667 |

| Permeabilitas vaporis aquae | kg/(mspa) | ≤0.91×10﹣¹³ | DIN 52 615 BS 4370 Pars 2 1973 |

| μ | - | ≥10000 | |

| Conductivitas Thermalis | W/(mk) | ≤0.030 (-20°C) | ASTM C 518 |

| ≤0.032 (0°C) | |||

| ≤0.036 (40°C) | |||

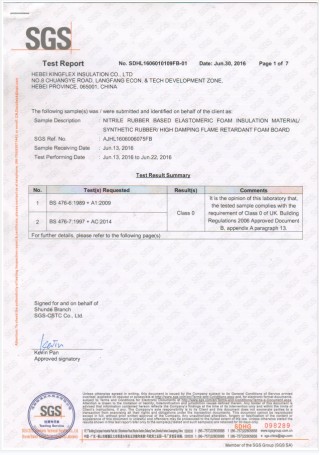

| Classificatio Ignis | - | Classis 0 et Classis 1 | BS 476 Pars 6 pars 7 |

| Index Propagationis Flammae et Fumi Evoluti |

| XXV/L | ASTM E 84 |

| Index Oxygenii |

| ≥36 | GB/T 2406, ISO4589 |

| Absorptio Aquae, % per Volumen | % | XX% | ASTM C209 |

| Stabilitas Dimensionis |

| ≤5 | ASTM C534 |

| Resistentia fungorum | - | Bonus | ASTM XXI |

| Resistentia ozoni | Bonus | GB/T 7762-1987 | |

| Resistentia ad UV et tempestates | Bonus | ASTM G23 | |

Commoda producti

Qualitati Aeris Interioris Amica: Sine fibris, sine formaldehydo, paucis VOCs, sine particulis.

Silentium: damnum vibrationis et sonitum prohibens.

Durabilis: nulla fragilis moratur vapor.

Processus Fabricationis Laminae Spumae Rubbericae Insulationis Thermalis Kingflex

Tres partes principales in fabricatione insulationis spumae elastomericae cellulis clausis adhibitae sunt hae:

Mixtura gummi synthetici, typice gummi nitrili butadieni (NBR) et/vel monomer ethyleni-propyleni-dieni (EPDM); Polyvinylchloridum (PVC), agens spumans chemicus.

Hae partes in magno mixtorio coniunguntur, plerumque in fasciculis quingentarum librarum vel plus. Deinde mixtura per apparatum extrudendi transit ut formam vel figuram particularem formet, plerumque vel tubum rotundum vel laminam planam. Forma in furno ad temperaturam specificam calefacta est, processus qui spumam chemicam ex solido in gas mutare facit. Cum hoc fit, milia minutarum alveolarum aerearum (cellularum)—quae omnes connexae sunt—formantur. Forma diligenter refrigeratur ut hae cellulae integrae et integrae maneant, structuram cellularem clausam materiae servantes. Deinde ad magnitudinem secatur et ad transportationem involucris includitur. Spumae elastomericae sine usu chlorofluorocarbonum (CFC), hydrochlorofluorocarbonum (HCFC), vel hydrofluorocarbonum (HFC) fiunt, quod eas aptas ad severissimas specificationes ambientales reddit.

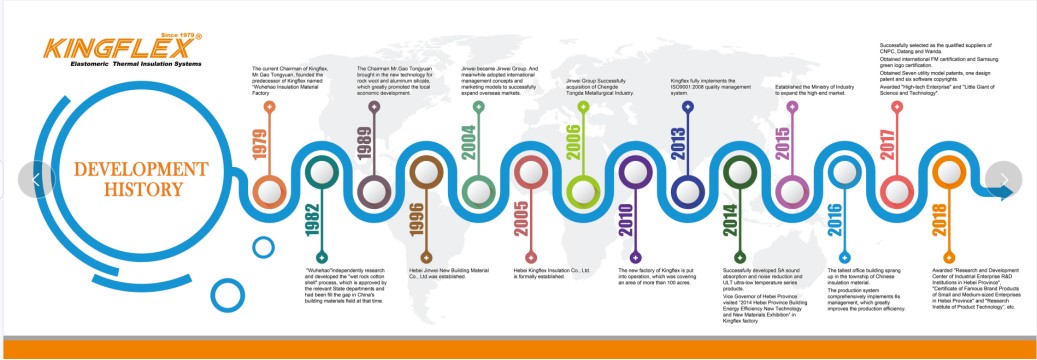

Societas Nostra

Exhibitio societatis

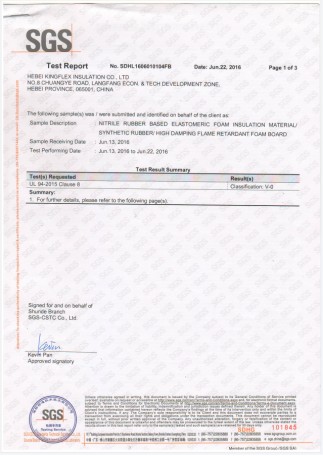

Certificatum

Categoriae productorum

-

Telephonum

-

Epistula electronica

-

Whatsapp