Lamina insulationis spumae gummi PVC NBR

Descriptio

Lamina insulationis ex spuma plastica e gummi est materia mollis ad calorem insulandum, calorem conservandum et energiam conservandam, fabricata technologia provecta domi et linea productionis continua plene automatica ex exteris regionibus importata, gummi butyronitrilico optimae efficaciae et polyvinylchlorido (NBR, PVC) ut materiis primis principalibus, aliisque materiis auxiliaribus altae qualitatis per spumam et cetera specialia procedendi ratione utens.

Dimensio Standardis

| Dimensio Kingflex | |||||||

| Tcrassitudo | Wmensa 1 | Wlatitudo 1.2m | Wlatitudo 1.5m | ||||

| Unciae | mm | Magnitudo (L*A) | ㎡/Volumen | Magnitudo (L*A) | ㎡/Volumen | Magnitudo (L*A) | ㎡/Volumen |

| 1/4" | 6 | Triginta × unum | 30 | Triginta × 1.2 | 36 | 30 × 1.5 | 45 |

| 3/8" | 10 | Viginti × unum | 20 | Viginti × 1.2 | 24 | XX × I.V | 30 |

| Dimidium unciae | 13 | 15 × 1 | 15 | 15 × 1.2 | 18 | 15 × 1.5 | 22.5 |

| ¾" | 19 | Decem × unum | 10 | 10 × 1.2 | 12 | 10 × 1.5 | 15 |

| 1" | 25 | Octo × unum | 8 | Octo × 1.2 | 9.6 | Octo × 1.5 | 12 |

| 1 1/4" | 32 | Sex × unum | 6 | Sex × 1.2 | 7.2 | Sex × 1.5 | 9 |

| 1 1/2" | 40 | Quinque × unum | 5 | 5 × 1.2 | 6 | 5 × 1.5 | 7.5 |

| 2" | 50 | 4 × 1 | 4 | 4 × 1.2 | 4.8 | 4 × 1.5 | 6 |

Scheda Datorum Technica

| Data Technica Kingflex | |||

| Possessio | Unitas | Valor | Methodus Probationis |

| Ambitus temperaturae | °C | (-50 - 110) | GB/T 17794-1999 |

| Ambitus densitatis | kg/m³ | 45-65 kg/m³ | ASTM D1667 |

| Permeabilitas vaporis aquae | kg/(mspa) | ≤0.91×10﹣¹³ | DIN 52 615 BS 4370 Pars 2 1973 |

| μ | - | ≥10000 | |

| Conductivitas Thermalis | W/(mk) | ≤0.030 (-20°C) | ASTM C 518 |

| ≤0.032 (0°C) | |||

| ≤0.036 (40°C) | |||

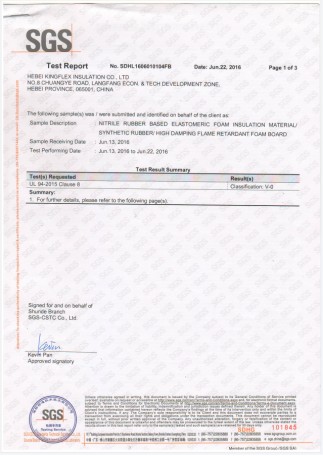

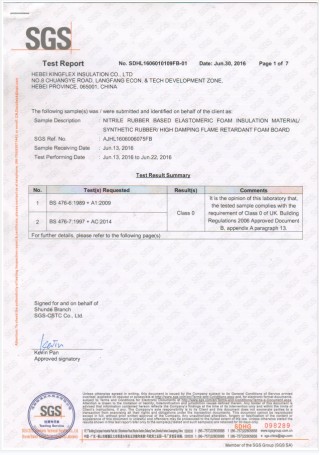

| Classificatio Ignis | - | Classis 0 et Classis 1 | BS 476 Pars 6 pars 7 |

| Index Propagationis Flammae et Fumi Evoluti |

| XXV/L | ASTM E 84 |

| Index Oxygenii |

| ≥36 | GB/T 2406, ISO4589 |

| Absorptio Aquae, % per Volumen | % | XX% | ASTM C209 |

| Stabilitas Dimensionis |

| ≤5 | ASTM C534 |

| Resistentia fungorum | - | Bonus | ASTM XXI |

| Resistentia ozoni | Bonus | GB/T 7762-1987 | |

| Resistentia ad UV et tempestates | Bonus | ASTM G23 | |

Commoda producti

• Transmissionem soni exterioris ad interiora aedificii minuere

• Sonos reverberantes intra aedificium absorbere

• Efficientiam thermalem praebere

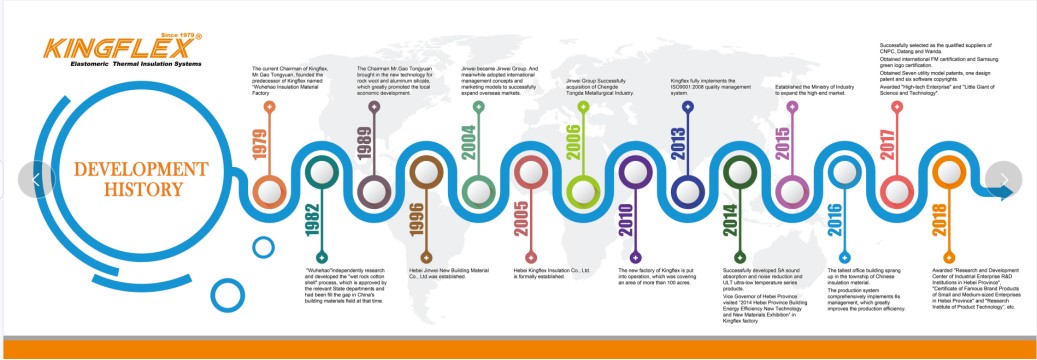

Societas Nostra

Exhibitio societatis

Certificatum

Categoriae productorum

-

Telephonum

-

Epistula electronica

-

Whatsapp